Description

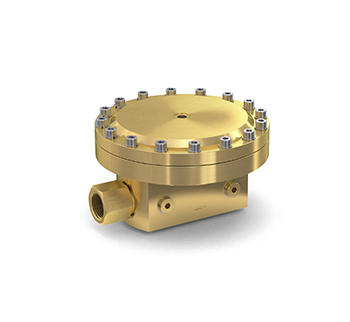

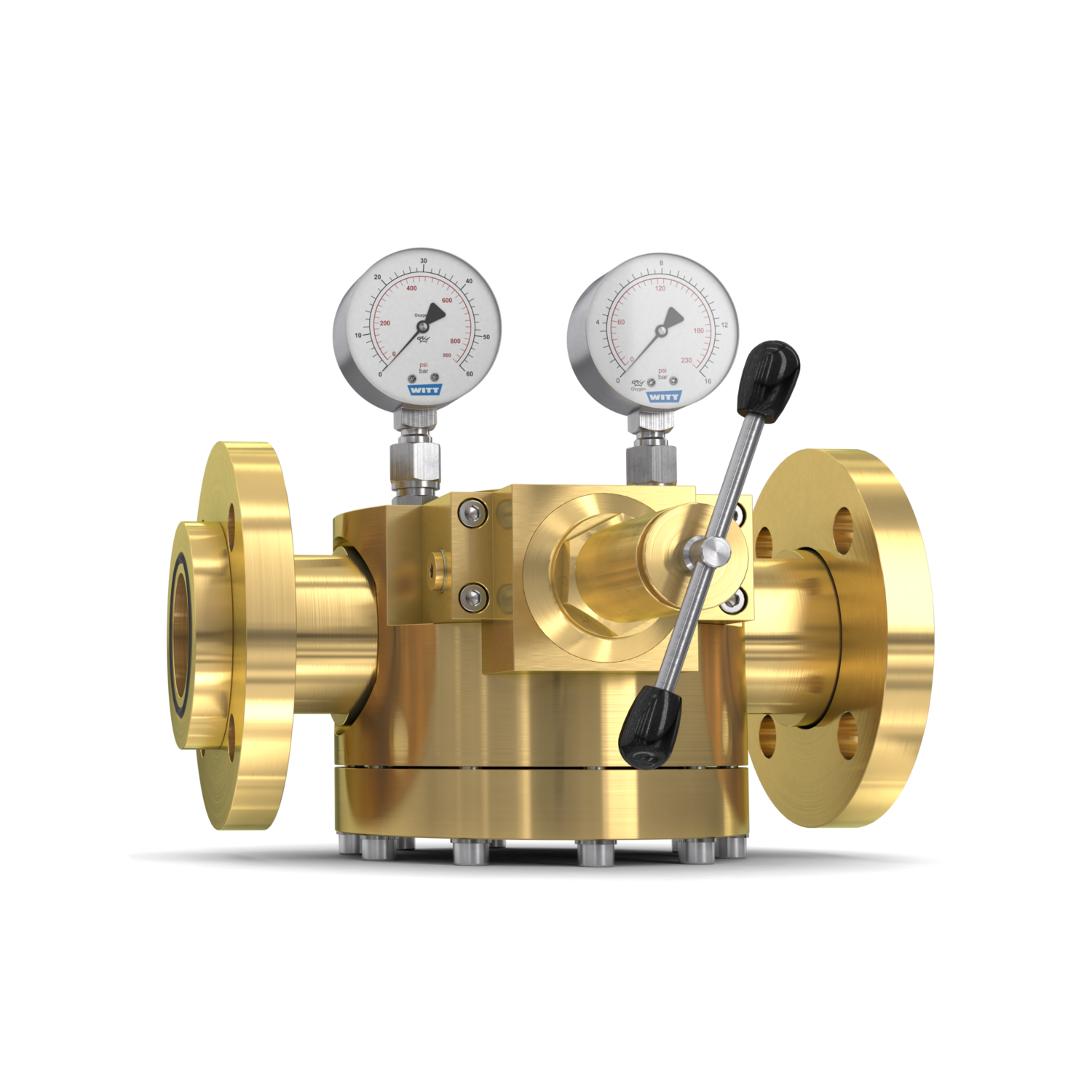

High-performance dome-loaded pressure regulator-set.

For high and varying flows requiring maximum pressure stability.

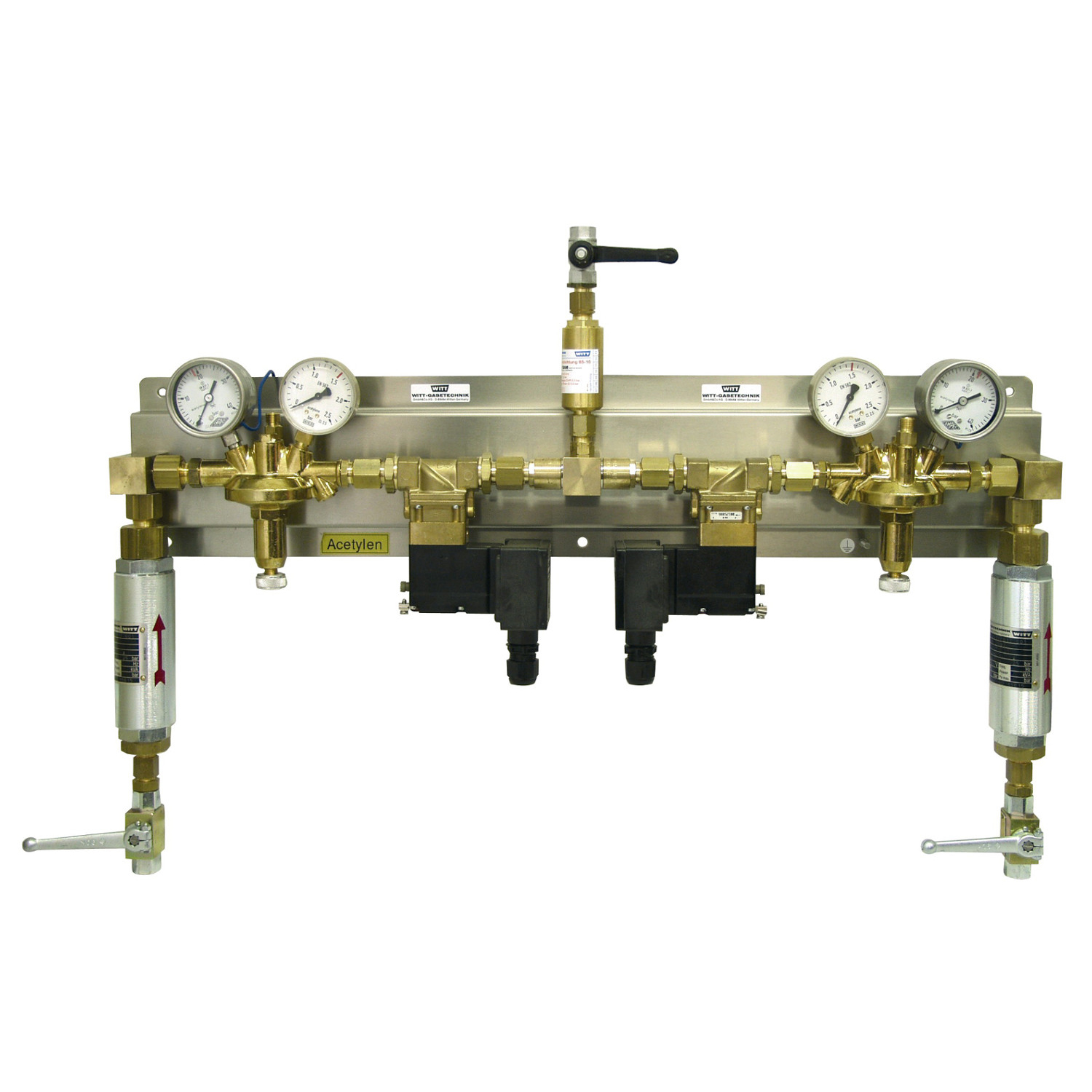

A complete solution, applicable as a manifold pressure regulator per DIN EN ISO 7291.

Features

- Pilot Control Tube (PCT)

One of the features enabling highly accurate control of outlet pressure - Balanced Seat Design (BSD)

Further enabling control precision, high reliability and low maintenance - A complete solution, ready to use

With integrated pilot pressure regulator, and stainless steel pressure gauges, completely assembled and tested - Own-medium controlled

Enabling autonomous operation - Closed system

No gas is released to the atmosphere - Simple to install and operate

Removable spindle enables the simple setting of the required outlet pressure. Can be positioned at any angle/orientation. For indoor and outdoor installation.

Operation / Usage

- Ideal for process gas supply where pressure accuracy is required even when inlet pressures and flow rates are varying.

- High flow rates and outlet pressure accuracy are achieved, even when the difference between inlet and outlet pressures is small.

- Own-medium controlled, with the integrated pilot gas regulator, meaning no separate gas supply is required.

Maintenance

- Annual testing of body leak tightness is recommended.

- Depending on the application, moving wetted parts may need periodic replacement.

- Device-specific Maintenance-Kit is available upon request.

Approvals

- Company certified according to ISO 9001, ISO 22000 and PED 2014/68/EU Module H

- CE-marked according to PED 2014/68/EU

- ATEX 2014/34/EU with ignition hazard analysis according to EN 1127-1, DIN EN 13463-1 and ZH1/200

- Analysed for Food Safety per HACCP-Analysis

- Fulfils the requirements of EU Regulations (EC) 1935/2004, and (EC) 2023/2006

- Fulfils the requirements of German Food and Feed (LFGB) Law, and is suitable for contact with food gases

Option:

Lockable spindle hood against unauthorized adjustment

Available upon request

- Certificates and test reports

- Other Dome types

- Switchover systems / parallel supply systems

- Customer-specific / customised versions.