Description

Gas mixing systems for 2 defined gases, designed for packaging using a protective atmosphere in the food industry.

Applicable for all types of packaging machines; whether vacuum, thermoforming, pillow bags or manually-sealed compartments. The KM-FLOW uses electronic mass flow controllers (MFC) instead of conventional proportional valves for mixing gases. Combined with an analyser results a maximisation of the packaging quality accompanied by minimisation of the gas consumption. This efficient workflow can be ideally realised with MFC.

Capacity range 25 up to 500 Nl/min for each gas line. Ensures a constant, accurate mixture when large or very small volumes are needed.

Benefits:

- simple to operate via touchcreen

- freely programmable gas mixtures can be selected at the press of a button or by bar code scanner

- simplified analysis of results by digital data bus

- optimised gas consumption helps to reduce costs, cause user definable gas quantity for each different product (only in combination with an analyser)

- low maintenance

- easy to read display

- data transfer via USB port

- administration of product names for individual positioning

- measured data storage

- user level with different access authorisation

- up to 3 mixers cascadable. One unit with display and others as black-box realised

High Process Reliability:

- data log

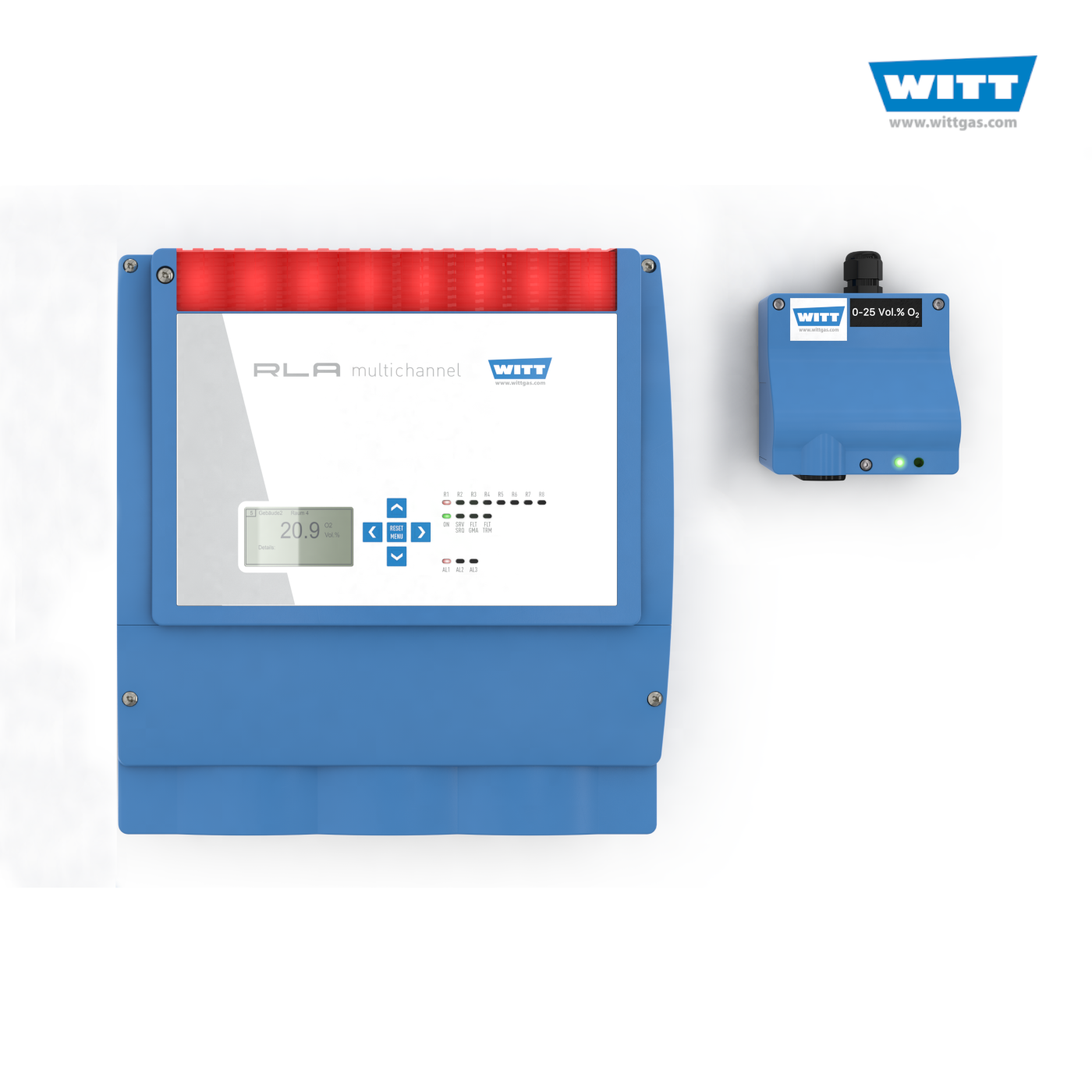

- permanent control of the O2-concentration

- electronic control of the sample gas, alarm signals are given if the set limits are exceeded and a potential-free contact operates to e.g. auto-stop your machine to avoid quality problems

- lockable transparent door for protection of settings (option)

- independent of pressure fluctuations in the gas supply

- independent of packing speeds

- independent of package sizes

Maximum Hygiene:

- splash-proof, robust stainless steel housing

- smooth and easy-to-clean surface

Options:

- integrated data logger

- measuring results data transfer via Ethernet

- bar code scanner for product names selection

Other models, options and accessories available on request. Please identify the individual gases at the time of enquiring!

Our gas mixers are always aligned to the needs of the customer. Please tell us your requirements, we will realise them.