Description

WITT non-return valves for reliable protection against dangerous reverse gas flow. Flow-optimized valve system causes very low pressure drop at minimal noise emission. Every non-return valve 100% tested.

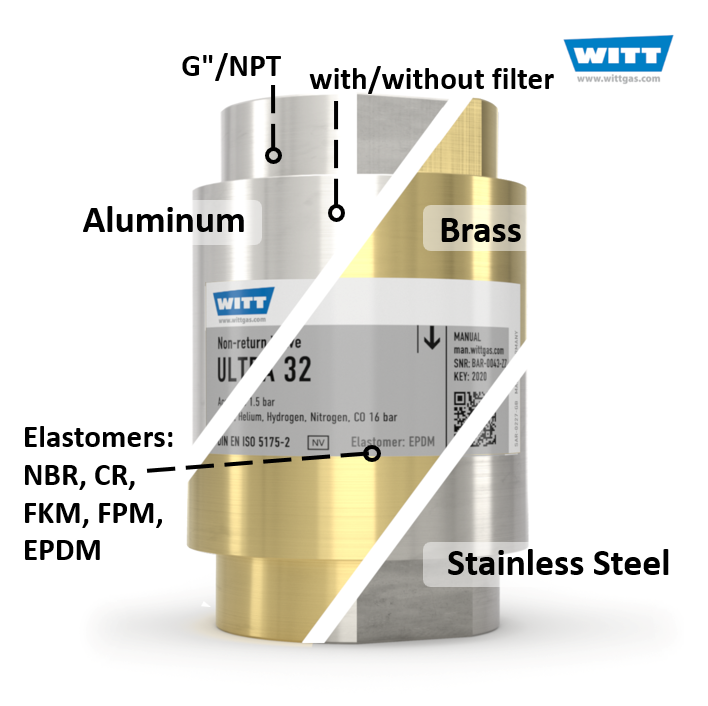

ULTRA 32 is based on ULTRA 30 and is customized according to the requirements of the customer – ideal for special requirements. A modular system which allows flexible material combinations for housing and sealings.

Combination possibilities

- housing available in brass, stainless steel or aluminium

- sealings of NBR, CR, FKM, EPDM, FFKM for example

- with or without dirt filter in gas inlet

Benefits

- precisely tailored design for special requirements. For example corrosive environments, acetylene, ultra-lightweight construction, temperatures above 70 °C / 158 °F

- a spring loaded non-return valve prevents back feeding of gases which could lead to unwanted gas mixtures

- low pressure drop – using complex valve assembly with low opening pressures (approx. 5 mbar)

- stainless steel filter (100 μm) in the gas inlet protects the non-return valve against dirt contamination, extending the service life

- flow-optimized valve system for:

– ultra low pressure drop

– minimal noise emission

- no leaks – using of a spring loaded valve assembly with elastomer sealing

- in accordance to DIN EN ISO 5175-2

- diverse applications – useful for many technical gases

- reduce installation costs – the spring loaded valve is not affected by gravity and may be installed in any orientation

Operation / Usage

- non-return valves are used to protect equipment and pipelines against dangerous reverse gas flow. Use is possible for applications according to EN 746-2

- WITT non-return valves may be mounted in any position / orientation

Maintenance

- annual testing of the non-return valve and body leak tightness is recommended

- WITT is happy to supply special test equipment

- non-return valves are only to be serviced by the manufacturer

Approvals

Company certified according to ISO 9001 and PED 2014/68/EU Module H

CE-marked according to PED 2014/68/EU

Designed for Oxygen Service in accordance with EIGA 13/20 and CGA G-4.4: Oxygen Pipeline and Piping Systems

Cleaned for Oxygen Service in accordance with EIGA 33/18 and CGA G-4.1: Cleaning of Equipment for Oxygen Service