Description

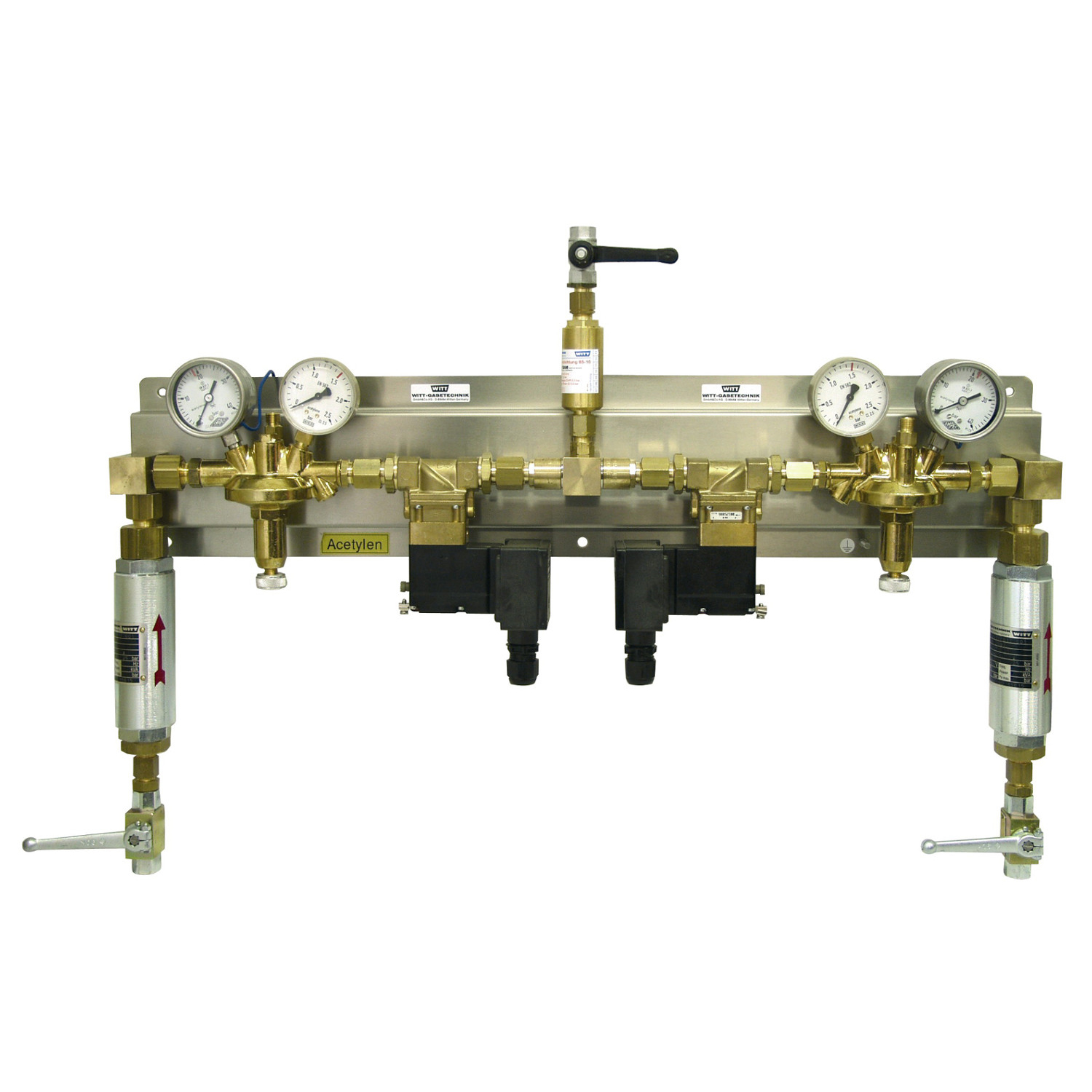

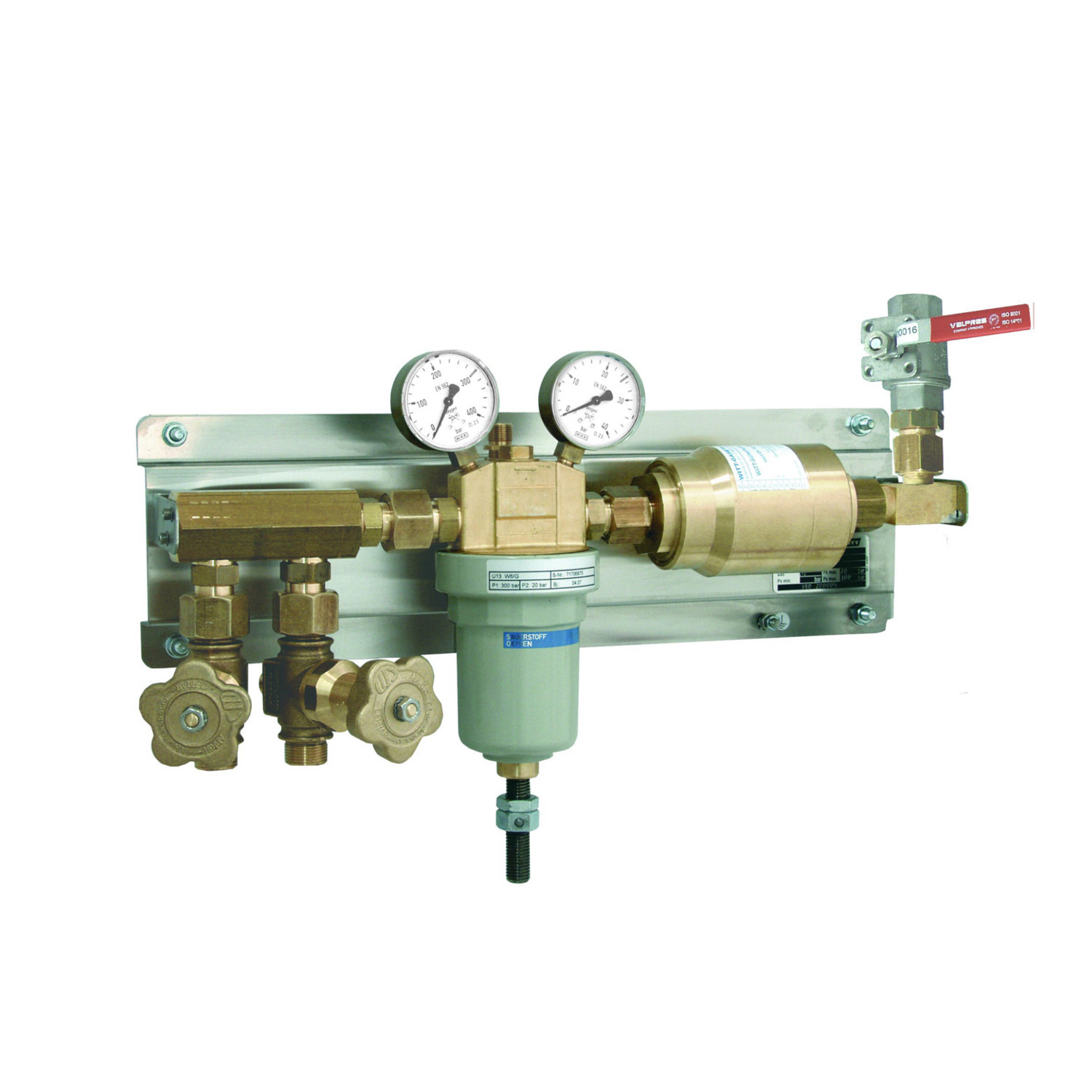

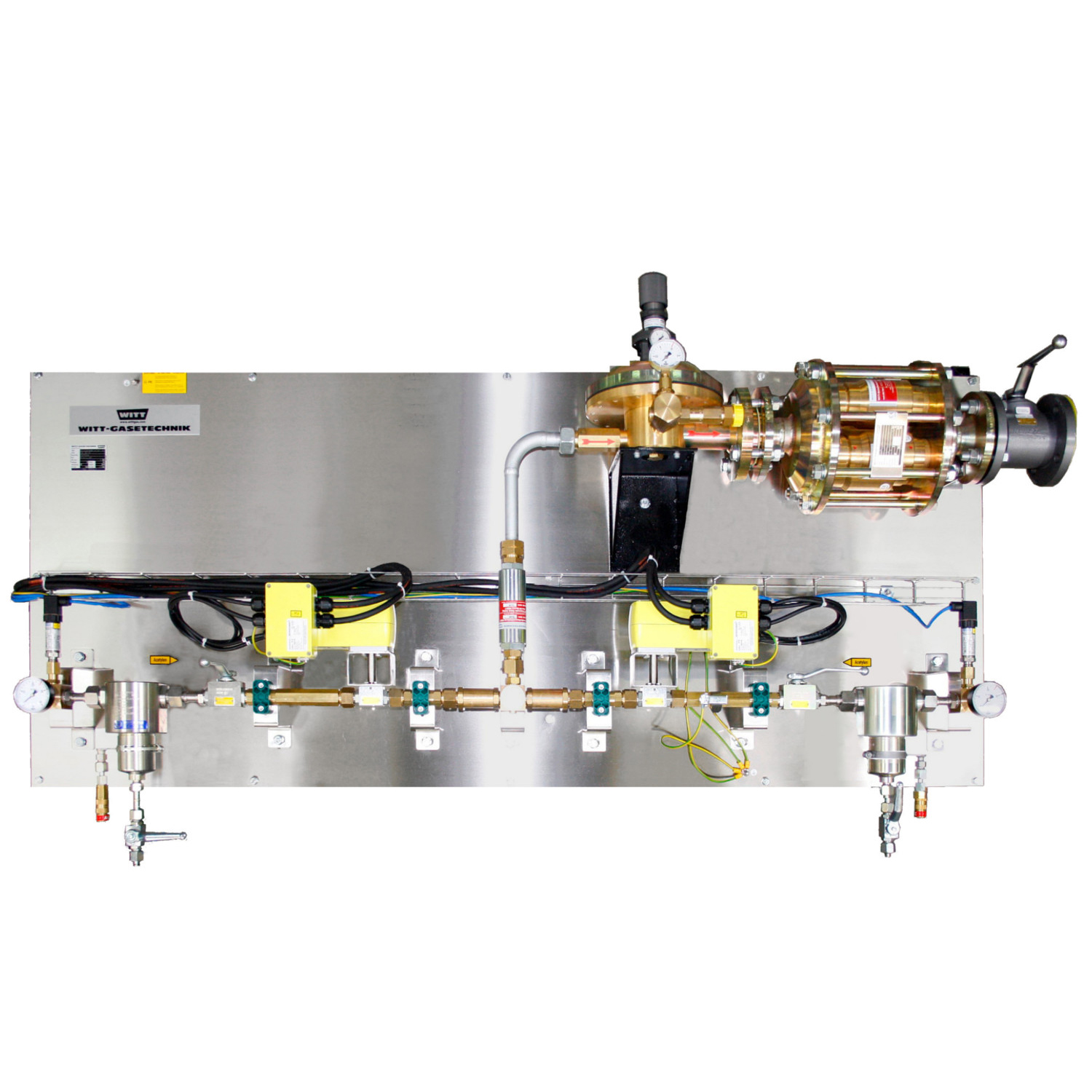

Outlet point with integrated gas filters for cutting machines with fuel gas, heating oxygen and cutting oxygen.

Benefits:

- inlet with fittings

- reliable filtering performance increases the service life of downstream fittings and equipment by gas filter 622 (40 μm)

- ball valve in inlet signals clearly position OPEN / CLOSED respectively gas flow/gas stop

- with safety device 85-10, against the reverse gas flow and flashbacks according to DIN EN ISO 5175

- quick and easy wall mounting

- compact design on nickel-plated square tube

- completely mounted and tested

Operation / Usage:

- Outlet points at the end of gas supply, verified with local required consumption rate

- Applicable for cutting machines

- Outlet points will be supplied according to our standard program or your special design

Assembly:

- Nickel-plated square tube. For withdrawal of:

1x Acetylene

inlet: soldering end 21.3 mm,

ball valve DN 10,

gas filter 622,

pressure regulator for outlet point,

safety device 85-10,

outlet: G 3/4 LH male with cone

1x Heating Oxygen

inlet: pipe coupler for copper- or stainless steel tube 15×1,

ball valve DN 10,

gas filter 622,

pressure regulator for outlet point,

safety device 85-10,

outlet: G3/4 RH male

1x Cutting Oxygen

inlet: pipe coupler for copper- or stainless steel tube 15×1,

ball valve DN 10,

gas filter 622,

pressure regulator for outlet point,

safety device 85-10,

outlet 3/4 RH male with cone

- completely mounted and tested

Approvals

Company certified to ISO 9001

Cleaned for Oxygen Service according to EIGA IGC Doc 13/12/E: Oxygen Pipeline and Piping Systems