Description

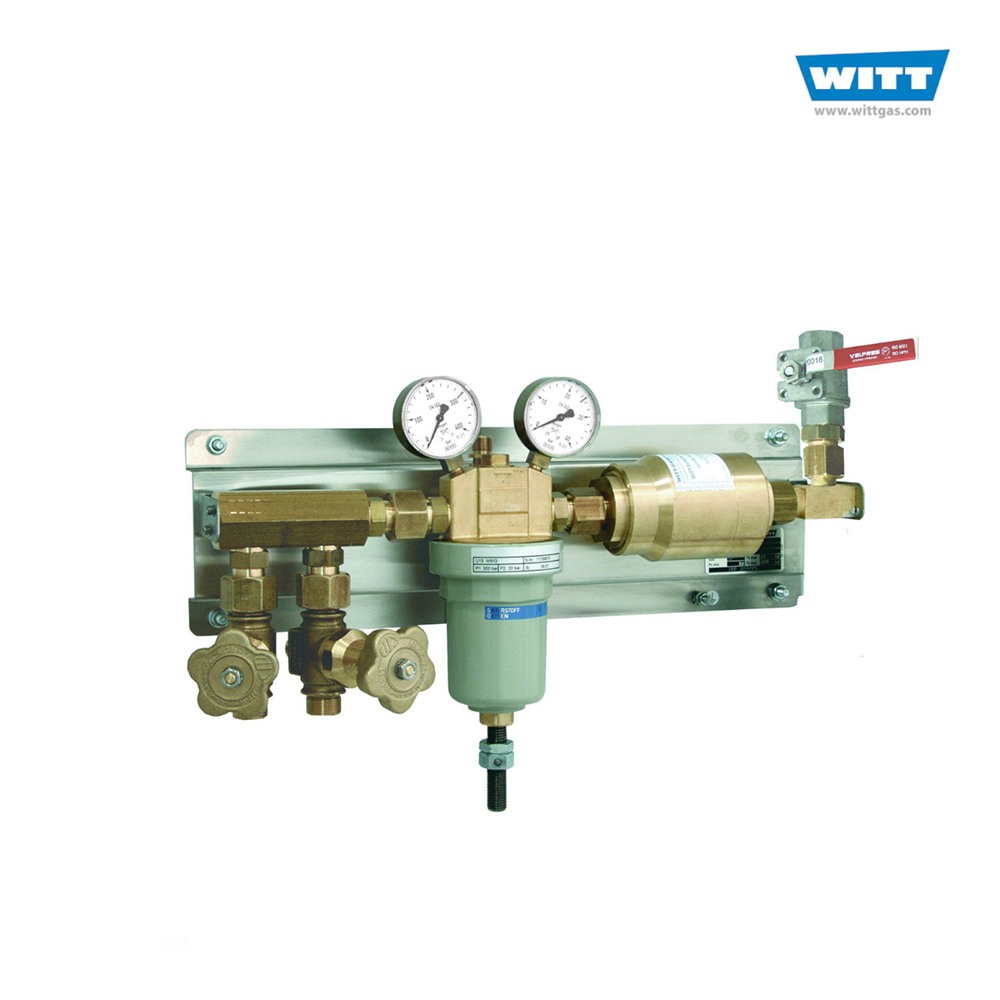

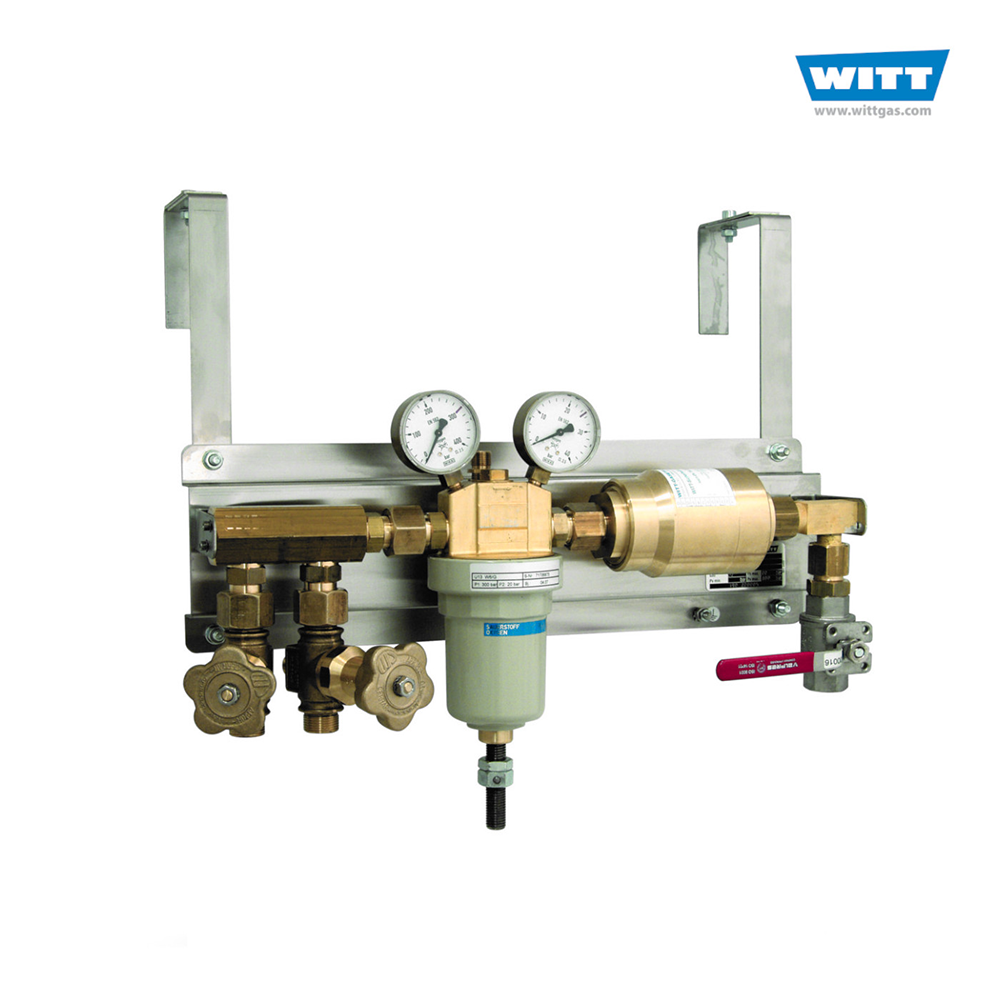

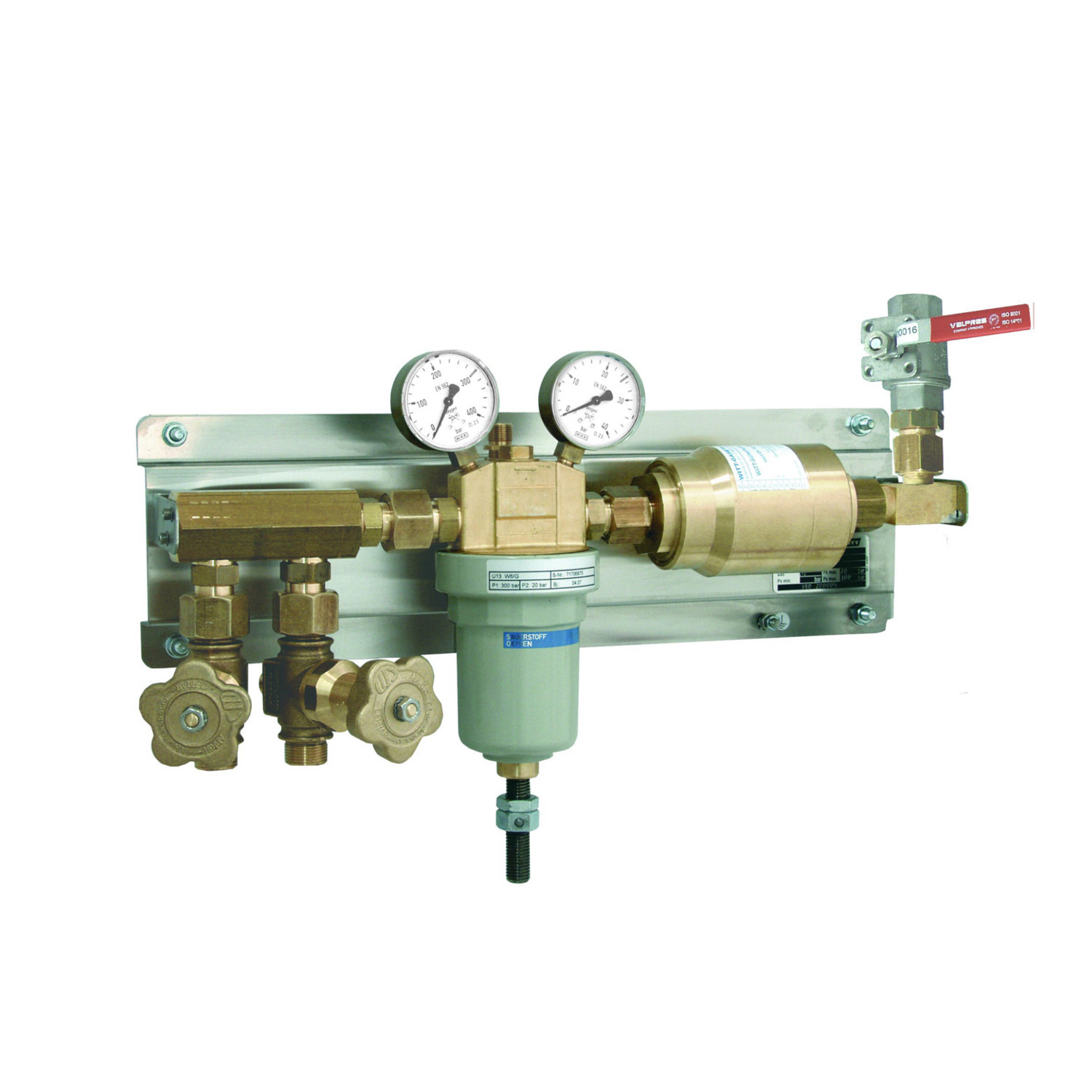

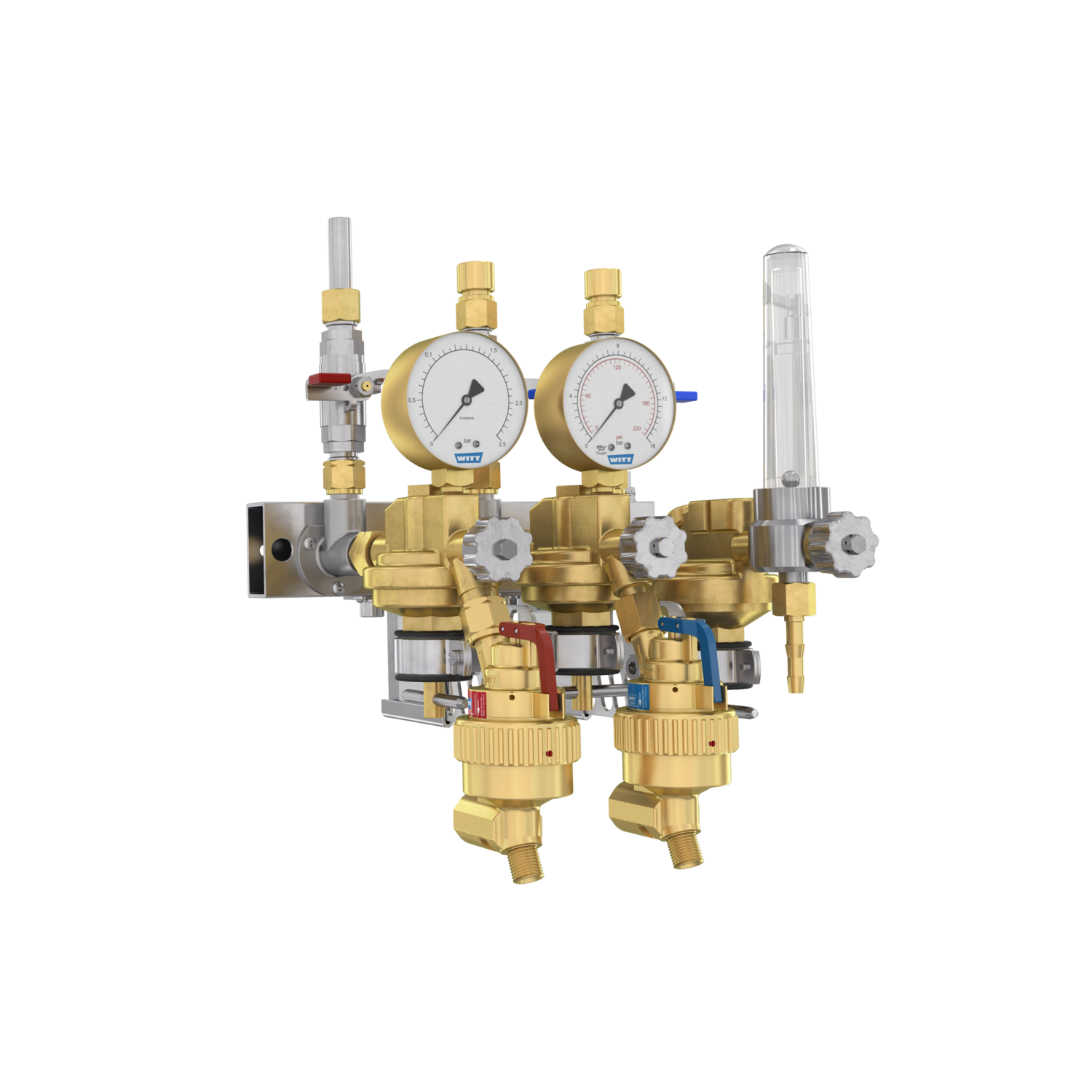

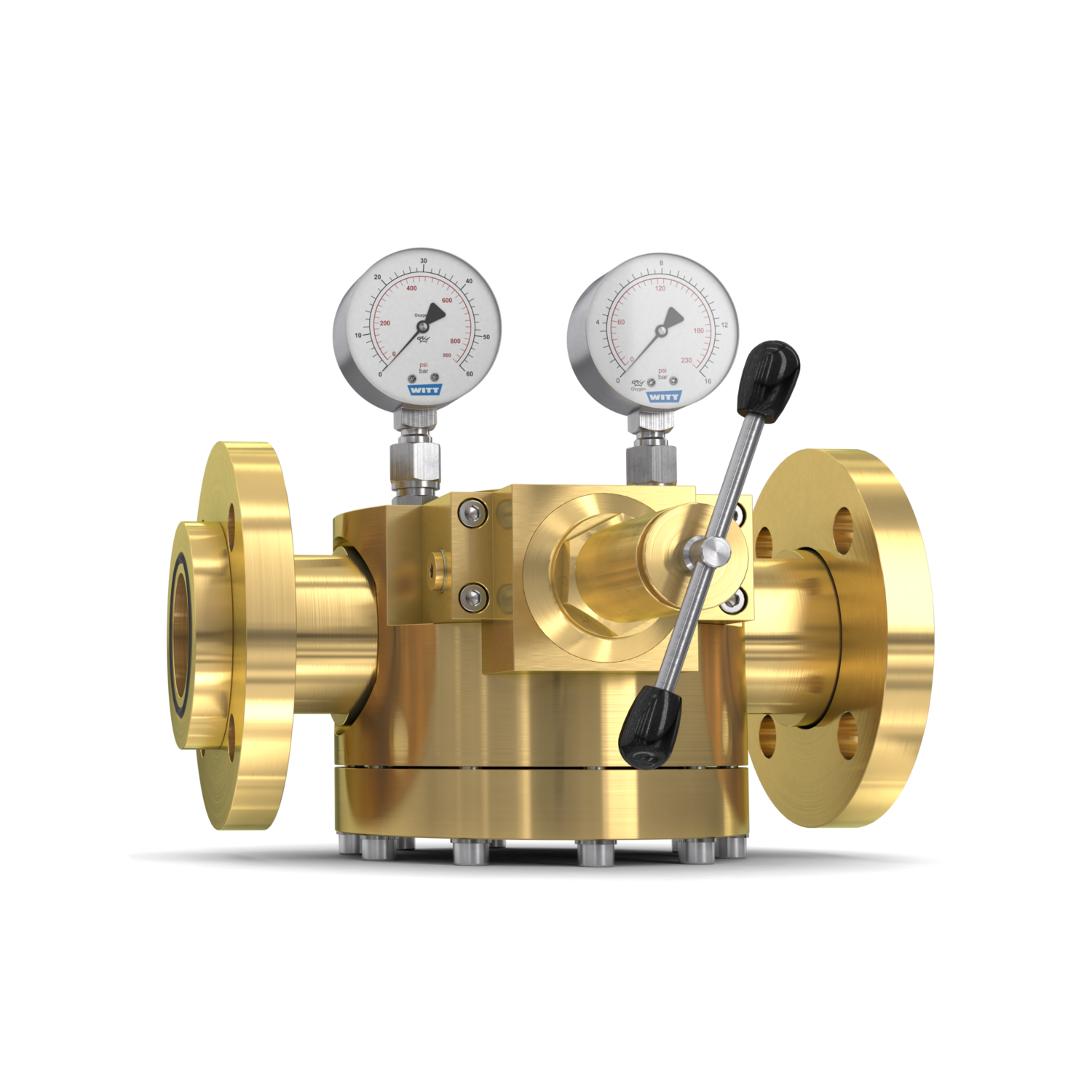

WITT Pressure regulating station 1×1 or manually changeable 2×1 for central gas supplies.

Every pressure regulating station 100% tested.

Benefits:

- pressure regulating station completely mounted and tested

- stationary or to fit on bundles

- quick and easy wall mounting

- compact robust design

- suitable for connection with bundles

- manifold pressure regulator according to DIN EN ISO 7291

Operation / Usage:

The pressure regulating station ensures continuous gas supply and control of a pipeline, which is connected with pipeline outlets and reduces the risk of accidents. Supplying from single cylinders is no longer necessary.

Assembly:

- 1×1 pressure regulating station 386NPL

- 2×1 pressure regulating station 386NPL manually changeable

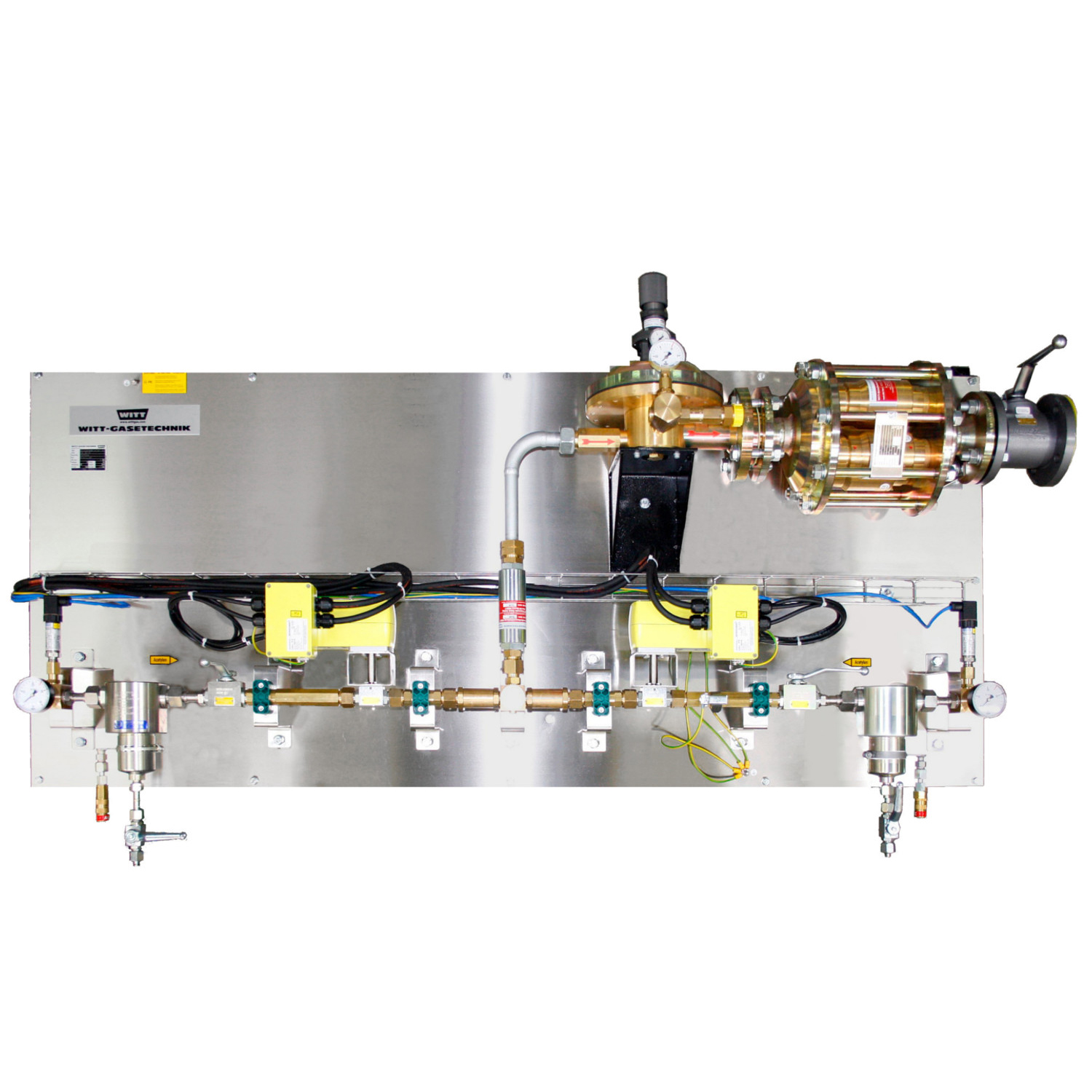

- maximally available up to 3×1 (on request)

consisting of:

high pressure gate valve 1x or 2x dependant on option

1x pressure regulator with blow off valve

1x ball valve in the outlet

- complete mounted and tested on stainless steel plate

Options:

- flush valve

- second outlet and/or up to 60 bar outlet pressure (special equipment)

- flexible hose standards for connection of pressure regulating station with gas supply (cylinder, gas cylinder manifolds, bundles, …), adapter suitable for bundle connections

- screw connection for pipe (soldering end, WITTFIX, welding end)

- pressure gauge with contacts

- safety device 85-30 according to DIN EN ISO 5175-1 against gas backflow and flashback

Approvals

Company certified to ISO 9001

Designed for Oxygen Service in accordance with EIGA 13/20 and CGA G-4.4: Oxygen Pipeline and Piping Systems

Cleaned for Oxygen Service in accordance with EIGA 33/18 and CGA G-4.1: Cleaning of Equipment for Oxygen Service