Description

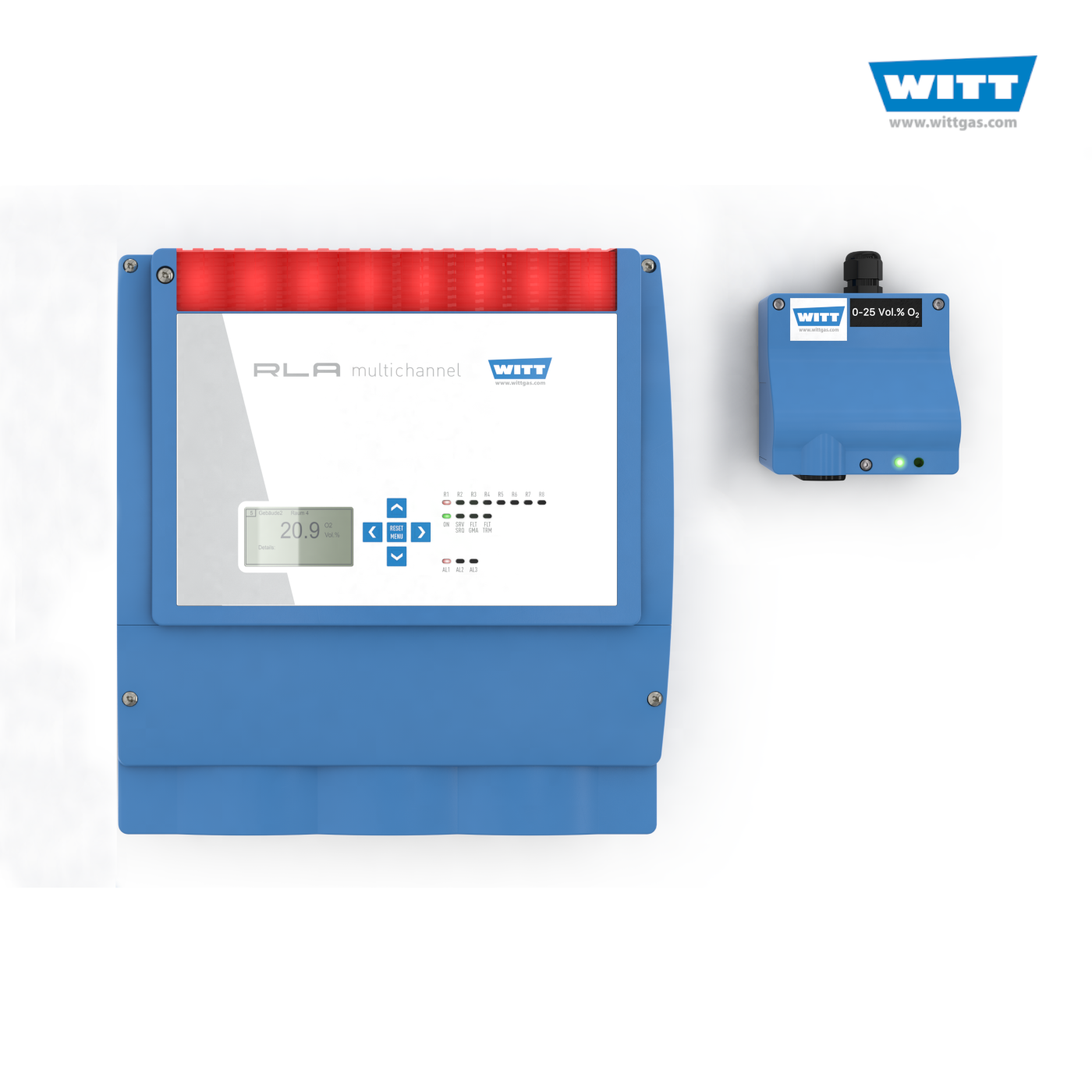

Electronic flow control system for modified atmospheres for flowwrap machines in the food industry and for room atmospheres e.g. for the storage of fruit and vegetables.

Cost Reduction:

- saves up to 30% of gas consumption by automatic controlling the required residual oxygen level to a pre-determined set point

- the non-destructive gas analysis guarantees quality of the packages and economy of the production

Easy Operation:

- simple calibration

- low maintenance

- easy to read display

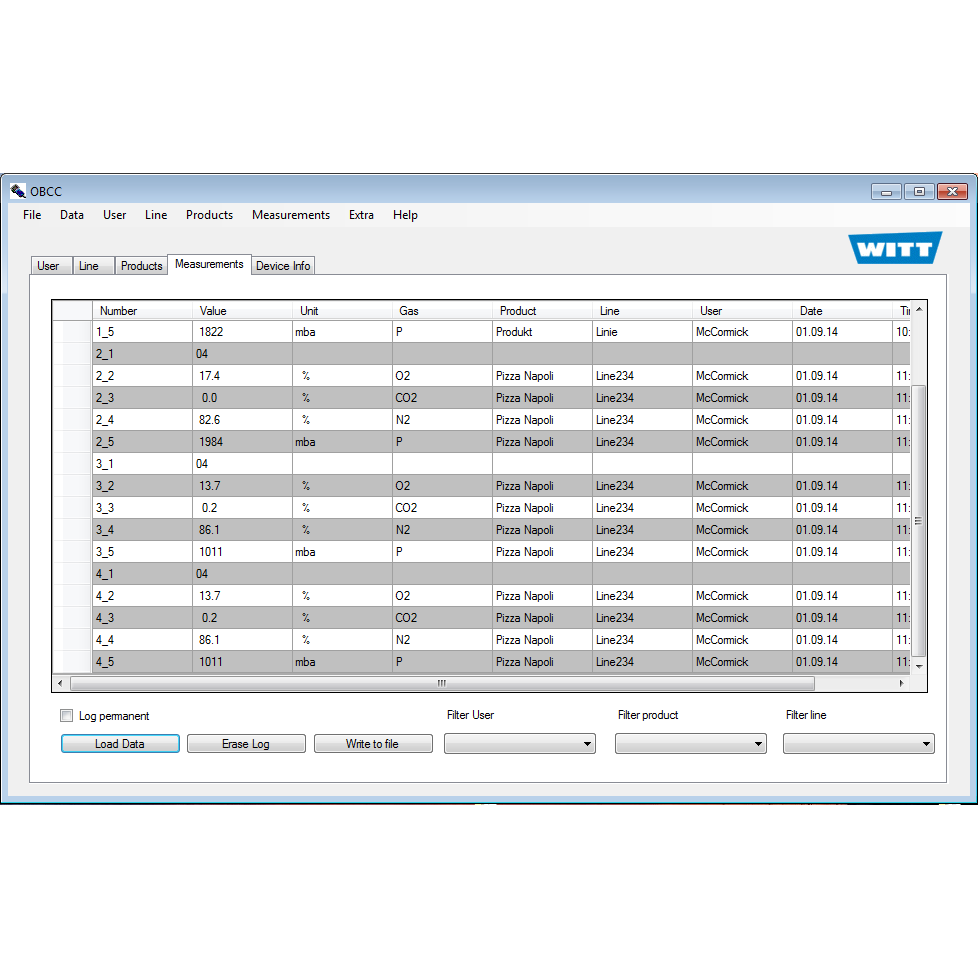

- integrated data logger

- USB connection for file transfer

- administration of product names

- simple to operate via touchscreen

- ethernet connection for network integration

- measured data storage

- user level with different access authorisation

- user-definable settings for each different product i.e. set point, alarm limits etc.

High Process Reliability:

- data log

- permanent control of the O2-concentration

- electronic control of the sample gas to the sensor

- lockable transparent door for protection of settings

- alarm signals are given if the set limits are exceeded and a potential-free contact operates to e.g. auto-stop your machine to avoid quality problems

- independent of pressure fluctuations in the gas supply

- independent of packing speeds (MAP)

- independent of package sizes (MAP)

Maximum Hygiene:

- splash-proof, robust stainless steel housing

- smooth and easy to clean surface

Documentation:

- Interfaces for the documentation and remote transfer of the settings and measured values

Options:

- fully automatic calibration

- bar code scanner for product names or user selection

- additional memory

- sample measurement via needle – also with additional sensor

Our gas mixers are always customised to the needs of the costumer. Please tell us your specifications, we will realise them.