Description

Gas mixing systems for 3 defined gases especially for flow packing machines or other continuous packaging processes in the food industry.

Capacity range up to approx. 684 SCFH.

For the exact pressure and flow capacity ratios, please see the technical data overleaf.

Easy operation:

- three single mixing valves (-3), each with a control knob and %-scale, provide infinitely variable mixture settings

- the flow of the gas mixture is controlled by a metering valve combined with a flow meter

Constant quality:

- independent of pressure fluctuations in the gas supply

- independent of packing speed (in permitted range)

High process reliability:

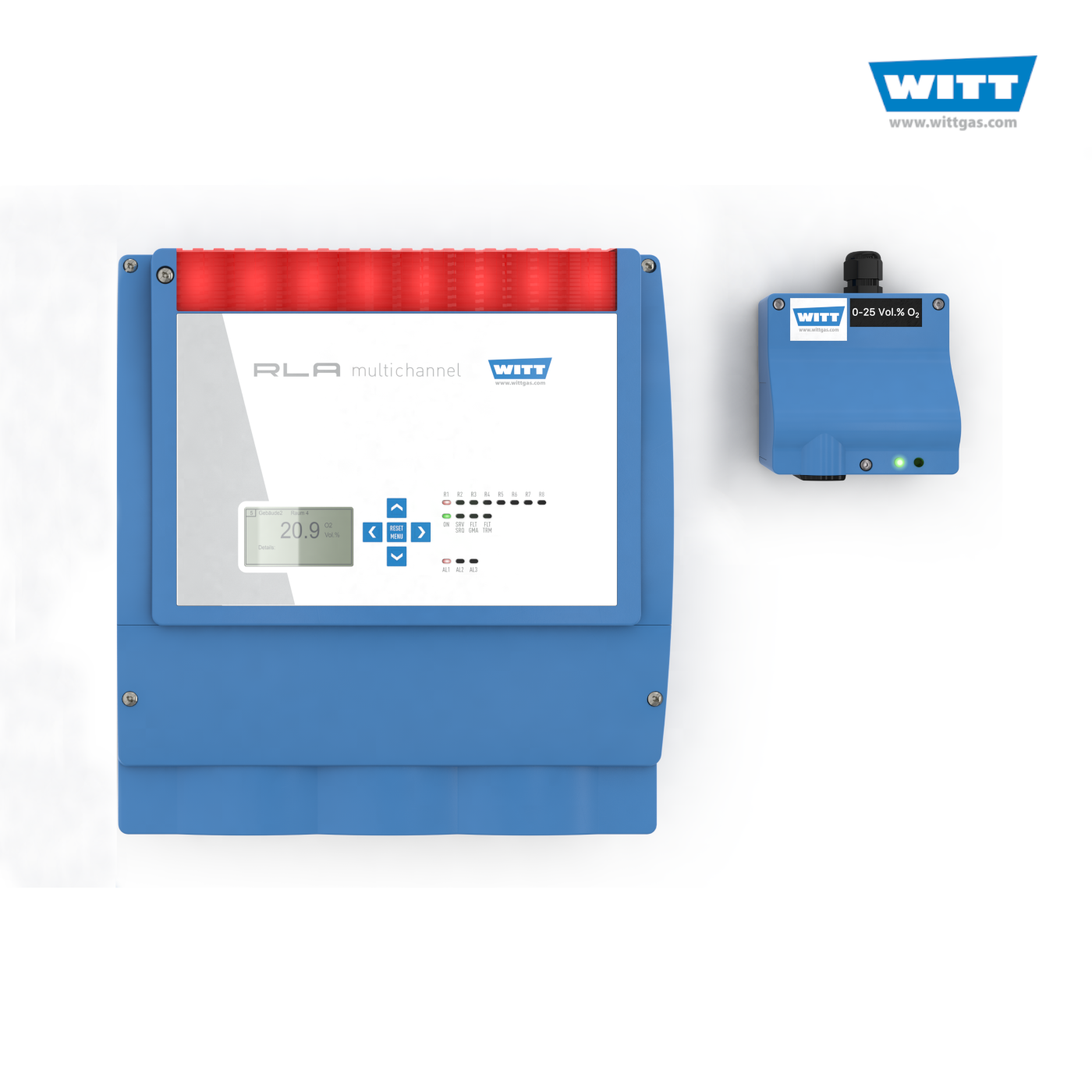

- alarm module NXT+: integrated inlet pressure monitoring with digital display for pressure (with analog pressure transmitters) plus optical alarm, adjustable alarm limits, obligation of acknowledgement, protection of alarms, interfaces for controlling external alarms etc.

- lockable transparent door for protection of settings

Maximum hygiene:

- splash-proof and robust stainless steel housing

- smooth and easy to clean surface

Other models, options and accessories available upon request. Please identify the individual gases at the time of enquiring!

Our gas mixers are always customized to the needs of the costumer. Please tell us your specifications, we will realize them.